In-Ear Monitor Case

I started thinking about a good case for in-ear monitors a long time ago, back in 2019, and I even wrote a post about that. Since then, the range of the related issues and the market have not changed at all.

What makes an IEM case good? That’s how I would phrase my needs:

- It should have room for the IEMs and a cable at least.

- It should prevent the earpieces from rubbing and scratching each other.

- It should prevent the earpieces from rubbing and scratching connectors and cable fittings.

- It should be somewhat stiff, though not too much.

- It should be convenient for putting in and taking out the earphones on the go.

You may have different needs, but these are the ones that I have.

There are no such cases in the market: original boxes are just boxes, always with one compartment only. Sometimes there’s a mesh inside, but it doesn’t do much good. The main thing is that functionally they are just expensive or cheap, high-quality or poorly made hard boxes of different sizes, and it is proposed to put IEMs with a cable in their only compartment. After a few months of holding the IEMs in a case like that, your favorite EA500LM, KATO, Wu or Glacier turn to shit, the coating traditionally begins to peel off from Aria, and simple ‘plastic’ earphones just get covered with a million scratches. This is a more or less suitable option of the existing ones (see here):

It’s hard, its volume is excessive, and it’s not convenient to put the earphones into it on the go because you have to figurately lay the cable around the perimeter of the case. Similar ones are also made by Tangzu with the same drawbacks.

As in the situation with the sound source switcher, I decided to take matters into my own hands and do it in a big way.

The design scheme is simple: a case should have separate compartments for the cable and each of the earpieces.

I found a leather crafter and started experimenting. The first prototype appeared.

The mistakes made:

- When hard buttons located at the bottom of the case snap into place, the earpieces can be damaged as they are held just under the buttons.

- I made a mistake with the height. It turned out to be excessive.

- I made a mistake with the depth. It wasn’t enough.

The second prototype:

The depth was radically increased, and the height was reduced. Instead of buttons, magnetic latches were used, which were now located at the top. Besides, the stiffness of the leather and the central divider in particular was radically increased.

The idea with the stiffness turned out to be all wet: when taking earpieces with large enclosures out of the case, the eartips fell off them. Moreover, I didn’t quite get into the ‘comfortable’ size again.

The third prototype:

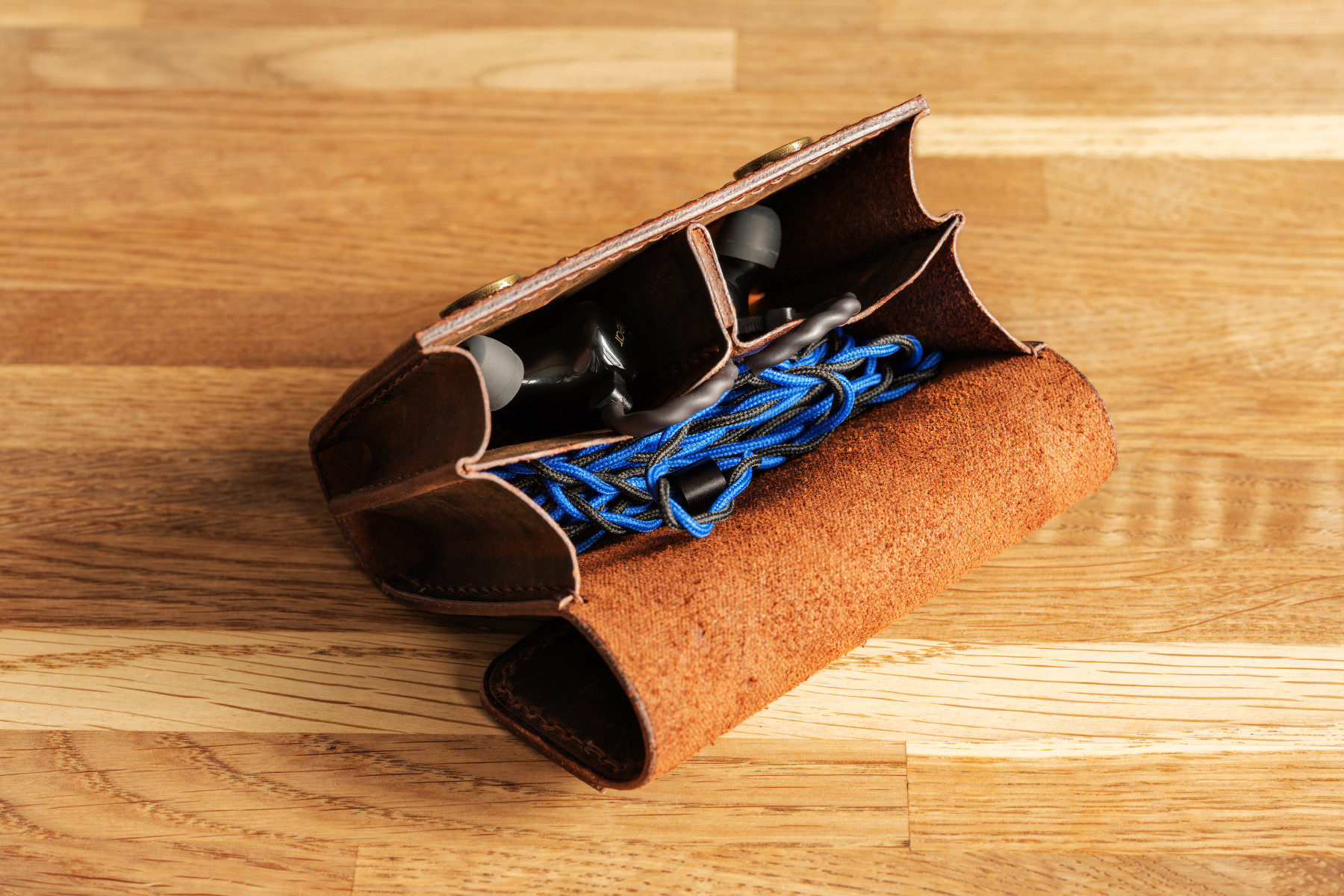

Soft leather; a thin, easily shaped longitudinal divider and, at the same time, a thick, dense perpendicular insert.

I went to work with this case for a week, adjusted the dimensions a little bit, then once again to make it, if not perfect, then close to it.

That’s how the final version appeared where everything is right on the money. Tiny cutouts for wires were also added on the longitudinal divider.

So, we take some earphones that are easy to scratch.

We wind up the cable on our fingers and put the earphones in the case.

Perfect.

Then we take some large earphones with a rigid cable, Truthear NOVA, for example.

And it’s good again.

We take small earphones, some StarCity 5 Pro, and put them in one compartment and then put the Shanling M0 Pro player in the other.

We can do it this way, too, although the earpieces will be scratching each other.

We take EA500LM and put them in a separate case by NiceHCK (see here).

Nothing will be scratched for sure any more, although it’s already not possible to quickly place the earphones on full alert from this position.

The case ‘swells up’, but closes quite easily.

Compared to the hard case I mentioned in the beginning, my option is:

- smaller in all three dimensions;

- not requiring figured laying of the cable;

- much more convenient to use on the go;

- suitable for a mini player.

The price of this case is $65. This is the money that I pay to the manufacturer, earning nothing from sales. I do it just for the fun. (I have a regular job where I’m actually paid nothing to sneeze at.)

If you want this case, send me an email. The time of manufacture will be from 1 to 3 weeks.

As for me, I’ll keep thinking about improving its ergonomics and expanding its functionality. There’s a lot more that can be done.

That’s it!